In addition to gas boilers with two heat exchangers, other options for the internal design of heating devices are also available. One of them is the combination of devices responsible for heating the living space and hot water supply into a more complex configuration. To choose a boiler for your needs, you need to study the properties of the bithermic heat exchanger, the advantages and limitations of its use.

Bithermic heat exchanger design

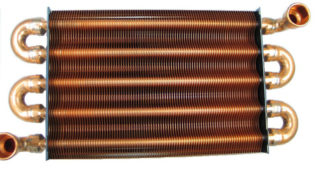

The device is also called “pipe in pipe”. This is due to the fact that the bithermic heat exchanger is ground for the implementation of two goals with one element. In the inner tube, water is heated for domestic needs, and in the outer one for heating. This heat exchanger is based on a copper tube of a specific design. In the context, its core contour has a diamond shape. It is connected to the inside of the main tube by soldering. This allows you to combine the mechanisms responsible for heating and water heating: for one, the outer space is used, for the other - the core. The outer tube is also equipped with plates that create greater contact with the combustion products. This improves heat transfer.

Instead of a set of hollow tubes, area division is used here. Water intended for one and another purpose circulates within its zones. Mixing does not occur. Like other types of devices, plate fins are used here to increase heat transfer. Other structural characteristics are already associated with the method of integrating the heat exchanger into the unit. Since gas boilers are heated using a burner, the casing is equipped with additional protective mechanisms. A safety unit is also installed to prevent electric current shorting.

Advantages and disadvantages

Pipe-in-pipe design features seriously affect the functioning of the unit being serviced.

The advantages of the device include:

- High efficiency and fluid heating rate. Using a burner flame saves on electricity and gas.

- Simplicity of design, rational layout, no need for a secondary exchanger and triple valve.

- Low probability of failure due to the fact that there is not a large number of parts.

However, this heat exchanger also has disadvantages. The main one is high demands on water quality. You should not choose an aggregate with such a model if the region has low quality water and a high percentage of salts: in this device they are deposited much more actively than in a separate one, and its maintainability is lower. If the mechanism fails, it is often easier to replace than to repair. To minimize the likelihood of such an incident, it is recommended to purchase filters that soften the water. Also, do not put the boiler in the "boiling" mode from below.

Comparison with split heat exchanger

A separate device is much easier to repair. If depressurization has occurred, it can be eliminated independently using a soldering iron. In combination with the unpretentiousness of water quality, this is the main advantage of these devices. However, heating does not occur as fast as when using a coaxial tube-in-tube coaxial exchanger.

The disadvantages of a separate device are its large size, the need for a crane with three strokes, a large number of parts, which increases the likelihood of breakage. Wall-mounted boilers often use lightweight and compact bithermic exchangers. Separate are usually used in floor units, often requiring placement in a separate room.

The principle of operation of the bithermic heat exchanger

The operating modes for heating the house and preparing hot water are different. In the first case, the coolant is heated during the combustion of fuel and then moves along the circuit. Water supply is implemented as a secondary option. The carrier is heated in the same way, the heat is given to containers allocated for household liquids. In this case, the water does not have to move along the contour; it is in the tank.

Most boilers with such a heat exchanger are capable of serving only one circuit at a time. In this case, parallel circulation of the coolant for heating and water heating does not occur. When the valve is closed, only liquid belonging to the heating system of the home moves through the exchanger. By opening the supply of hot water, the consumer suspends heating for the heating system for the duration of the intake. Serving two tasks in a row helps to spend the heat supplied by the burner more focused.

terms of Use

To buy a boiler with such a heat exchanger is only with confidence in the fairly good quality of the water used as a coolant. Be sure to put in a system of filters and softeners, because the device has low maintainability. This simple step should not be neglected in order to minimize the likelihood of needing to go to a workshop. The documentation attached to the boiler indicates the requirements for the coolant. You need to check that the water in the area matches them.

If the exchanger fails, contact a service center. In practice, it sometimes turns out that repairmen are reluctant to work with such devices and without guarantees, and as a result they have to buy new ones.

The structure is easily clogged with soot, and limescale deposits on it. This reduces the efficiency - one of its main advantages over separate options. It is advisable to periodically (every 2 years) clean the exchanger with the pump under pressure. Before carrying out it, you need to consult a technical center regarding the composition of the solution and the technology of the procedure. Errors in this matter easily lead to depressurization; in such an incident, the heat exchanger needs to be replaced. Well, if there is an opportunity to invite the master to the house - this will allow you to get qualified advice without dismantling the boiler.

Aggressive cleaning products are used only in extreme cases, if milder do not give the desired effect.

Comparison with split heat exchanger

With satisfactory water quality and the use of filtration and softening, a bithermic exchanger will give good efficiency and quickly heat up the liquid. It is also advisable to provide him with preventive washing every two years, but without consulting the master and knowledge of the intricacies of technology, this is not worth taking. In terms of maintainability, the device loses much to the separate one: the latter is easily repaired even at home, and the coaxial exchanger, if the operating conditions are not observed, often has to be replaced with a new one.

The operation of the boiler depends on the design of the exchange mechanism and on its material. Copper, from which bithermal products are usually made, has a high heat capacity, which makes it possible to make compact units suitable for wall mounting or placement in the kitchen.Exchangers are also aluminum and steel. In separate designs, stainless steel is often used. Its heat capacity is lower than that of copper, it is susceptible to corrosion and requires large volumes of coolant. Durable cast iron exchangers have been widely marketed in the past, and are now superseded by more lightweight options.

Bithermic heat exchangers have high efficiency, their design allows you to design more compact and lightweight boilers. The disadvantage of such devices is their susceptibility to overgrowing of walls with calcareous deposits.